Core Functions of Fracturing and Stimulation Additives

Rheology Control and Transport Efficiency: Defoamers, Friction Reducers, and Acids

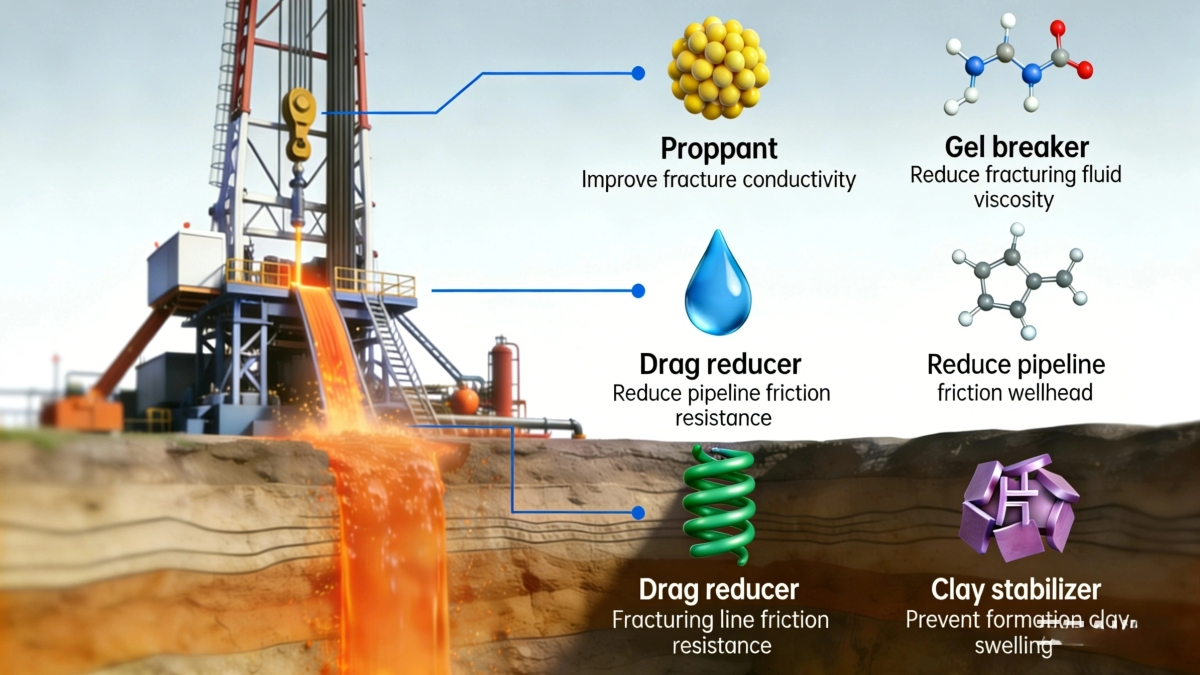

Additives used during fracturing and stimulation help adjust how fluids flow so proppants can move through and settle where they need to go. Defoamers get rid of trapped gas in foamed fluids, which brings back around 15 to 20 percent of pump efficiency that gets lost when foam creates cavitation problems. Friction reducers work wonders for reducing pressure loss inside tubing. These can cut down on pressure drop by as much as 70 percent, meaning operators can inject more fluid without needing new equipment. When it comes to acids like hydrochloric acid or various organic mixtures, they clean up damage near the wellbore area. But getting the concentration right is really important because if there's too much acid, it might dissolve things it shouldn't or cause unwanted deposits. Getting the right viscosity level is all about finding that sweet spot. If the fluid is too thin, proppants will settle out too soon. But make it too thick and the system demands way more power while limiting how complex the fractures can become. Looking at actual field results shows that good fluid engineering makes a big difference. Properly designed systems tend to spread proppants better across complicated fracture networks with multiple branches, sometimes improving distribution by about 40 percent according to what we've seen in practice.

Chemical Stability and Formation Compatibility: Key Selection Criteria

Additive performance hinges on chemical stability under downhole conditions—particularly temperature, salinity, and pH. Thermal degradation above 300°F (149°C) can deactivate friction reducers within hours, while pH incompatibility accelerates corrosion and scale formation. Formation mineralogy dictates risk exposure:

| Consideration | Sandstone Risk | Carbonate Risk |

|---|---|---|

| Clay Swelling | High (require stabilizers) | Low |

| Mineral Precipitation | Iron scaling | Calcium fluoride scales |

| Fines Migration | Critical (>30% perm loss) | Moderate |

Operators prioritize additives validated across realistic reservoir gradients. For example, clay stabilizers must resist wash-off during flowback to preserve permeability. Chemically stable formulations have reduced post-stimulation production declines by 22% compared to conventional alternatives in field trials.

Reservoir-Targeted Fracturing and Stimulation Additives

Formation-specific chemical optimization is foundational to effective reservoir stimulation. Fracturing and stimulation additives are engineered not just for function—but for compatibility, minimizing secondary damage while maximizing conductivity.

Carbonate Formations: Acid Blends and Dissolution Kinetics Optimization

Carbonate reservoirs demand acid systems that balance aggressive dissolution with controlled reaction kinetics. Hydrochloric-acid blends (15–28%) dominate, but their rapid reactivity requires retarders for deeper penetration. Optimization includes:

- Acid-gelling agents, which reduce fluid loss and enhance fracture propagation;

- Chemical retarders, slowing reaction rates by 40–60% at 300°F (149°C);

- Diverting agents, ensuring uniform coverage across heterogeneous zones.

Premature acid spending remains a critical risk—especially in high-temperature dolomite, where reaction rates escalate exponentially above 250°F (121°C). Retarded and emulsified acid systems extend effective penetration depth by 30–45% versus conventional treatments.

Sandstone Formations: Clay Stabilizers, Iron Control, and Fines Migration Mitigation

Sandstone stimulations require precise mitigation of mineral sensitivity. Clay stabilizers prevent swelling-induced permeability loss; iron control additives inhibit ferric hydroxide precipitation during acid contact; and fines control surfactants suppress particle mobilization. Leading solutions include:

- Quaternary amine stabilizers, offering permanent clay fixation without impairing conductivity;

- Reducing agents, maintaining soluble iron concentrations below 5 ppm during flowback;

- Fines control surfactants, reducing migration by 80% in high-velocity wells.

These measures directly address secondary formation damage—the leading cause of post-stimulation productivity decline. Optimized chemical packages increase production rates by up to 25% in high-illite sandstone plays.

High-Performance Fracturing and Stimulation Additives for Challenging Conditions

HP/HT Stability: Thermal Degradation Limits of Friction Reducers and Diverting Agents

When dealing with HP/HT wells running over 300 degrees Fahrenheit, additives tend to break down pretty fast which cuts fracture conductivity somewhere around 40% or so. The synthetic polymers used as friction reducers start losing their viscosity once temperatures hit certain points, forcing operators to crank up pump pressures and making it harder to design effective treatments. Diverting agents are another challenge too, particularly those biodegradable particles that need to hold together if we want proper zonal isolation. Most operators these days demand additives that have been tested according to API RP 19D standards. Ceramic microspheres along with surfactants that can stand heat have shown about 95% functionality even at 350F and 15k psi conditions in the Permian Basin, though results can vary depending on specific well conditions and application methods.

Slickwater Systems: Polymer vs. Non-Polymer Friction Reducers in Field Applications

The success of slickwater fracturing depends heavily on reducing friction so that operators can maintain those high injection rates above 100 barrels per minute. Traditional polyacrylamide based friction reducers do cut down on resistance about 70 percent, but there's a catch. These products tend to leave behind polymer residues inside the proppant pack which actually makes it harder for fluids to flow through later on. Some newer non-polymer options like certain advanced surfactant systems seem promising. They don't cause that same kind of formation damage problem while still achieving around 65 to maybe 68 percent friction reduction according to tests run in the Eagle Ford shale region. Sure, these alternatives cost more per gallon upfront, but when looking at the whole picture over time, companies find that they need to treat flowback water about 30 percent less often. This saves money in the long run because wells stay productive longer with fewer interruptions for maintenance and cleanup work.

Sustainability and Efficiency: Next-Generation Fracturing and Stimulation Additives

Eco-Optimized Additives: Biodegradability, Toxicity, and Flowback Performance Trade-offs

The latest generation of environmentally friendly fracturing and stimulation additives are helping operators be greener without hurting well performance down below. Most modern products will break down around 80 to 90 percent within about a month according to those OECD 301B standards, and they still hold up pretty well even when salt levels are high and temperatures run hot. There's always some give and take though. The less toxic versions tend to start flowing back about 15 to 20 percent slower because their surface interactions change. Get the mix right and these additives cut freshwater contamination risks by roughly 40 percent while keeping proppant moving through fractures just fine. Companies have started looking at the whole life cycle when developing new products, but real world results can vary quite a bit depending on factors specific to each reservoir including how hot it gets, what kind of salts are present, and the rock type itself.

Fluid Recovery Enhancement: Emulsifiers and Permeability Restorers for Reduced Trapped Saturation

New types of emulsifiers along with nano scale permeability restorers are making a real difference in how much fluid gets recovered from wells by cutting down on trapped saturation issues. These emulsifiers work by lowering the tension at the boundary where fracturing fluids meet existing hydrocarbons inside the rock formations. Field tests show this can boost flowback rates anywhere from 25 to 30 percent in tight sandstone reservoirs. At the same time, permeability restorers help prevent problems like clay swelling and movement of tiny particles within the formation, keeping over 90 percent of the original permeability intact after stimulation treatments. When these technologies are used together in integrated systems, operators typically see about half again as much flowback fluid coming back compared to traditional methods. The cost savings are also impressive, with water disposal expenses dropping around fifty cents per barrel. This means better operational results while also helping the environment since less fresh water needs to be drawn down and there's less waste to handle overall.

FAQ

What are the main functions of fracturing and stimulation additives?

Fracturing and stimulation additives are primarily used for rheology control, transport efficiency, chemical stability, and formation compatibility in challenging downhole conditions. They help optimize fluid flow, improve proppant distribution, and prevent secondary formation damage.

How do friction reducers work?

Friction reducers decrease pressure loss inside tubing by minimizing pressure drop, which enhances fluid injection efficiency. They are essential in both slickwater systems and high-temperature applications.

Why is formation-specific chemical optimization important?

Formation-specific chemical optimization ensures compatibility with reservoir conditions to maximize conductivity and minimize secondary damage, therefore improving overall well performance.

What are eco-optimized additives?

Eco-optimized additives are environmentally friendly options designed to reduce toxicity and enhance biodegradability while maintaining effective well performance.