Why Cleaning Agent Selection Directly Impacts Crude Oil Recovery Rate

Interfacial tension reduction and wettability alteration: Core mechanisms for residual oil mobilization

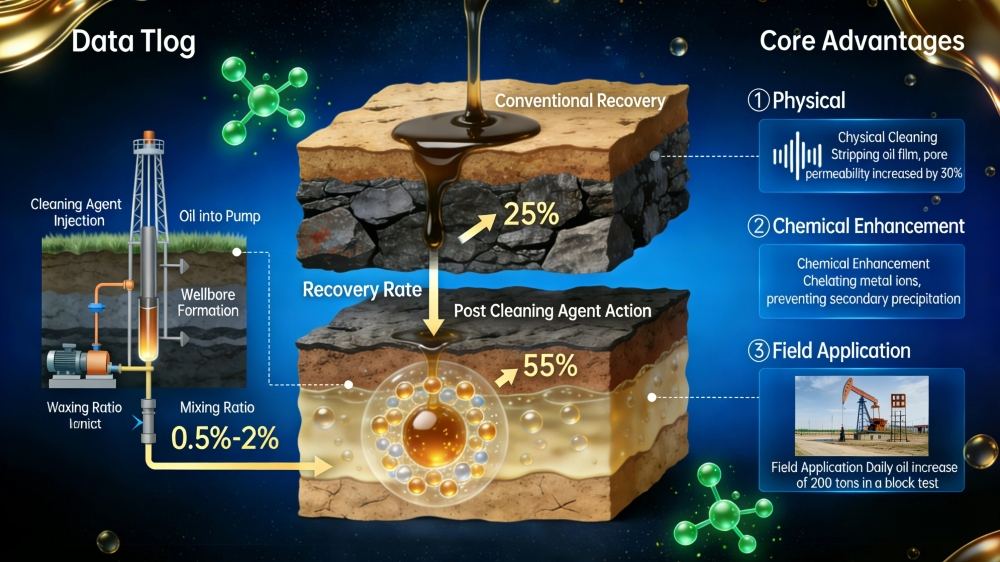

Cleaning agents work their magic on stuck crude oil via two main processes that go hand in hand: they lower the tension between oil and rock surfaces, and they change how the reservoir interacts with fluids from being oil-friendly to water-friendly. When this surface tension drops, it basically makes those tiny oil droplets easier to move around since the capillary forces holding them back aren't so strong anymore. At the same time, changing the wetting properties helps water sweep through the formation better and pushes oil off the sides of the pores. Field tests show these combined effects can cut down leftover oil by about 12 to 18 percent in sandstone deposits according to research published in engineering journals. For oil companies, this double punch approach forms the backbone of what's called enhanced oil recovery, especially useful in older fields where regular water injection just isn't cutting it anymore and starts giving less and less extra oil for all the effort.

Key performance criteria: HLB balance, thermal/chemical stability, and reservoir compatibility

When it comes to how well cleaning agents actually work in the field, there are really three main factors that matter most: the hydrophilic-lipophilic balance or HLB for short, how stable they stay when exposed to reservoir temperatures, and whether they play nicely with the minerals and brines found in formations. Getting the right HLB helps create those stable microemulsions even when salt levels and temps fluctuate around the place. Most important is keeping things stable at those extreme temperatures between 250 and 300 degrees Fahrenheit because otherwise the surfactants just break down during steam operations. The third piece is making sure these cleaners don't react badly with common ions like calcium and magnesium that tend to form deposits and block pores in rock formations, which nobody wants since that leads to serious problems with injection rates. We've seen plenty of field evidence showing that when all three of these factors line up properly, recovery rates jump by somewhere around 20-25%, way better than what happens when companies only focus on optimizing one parameter at a time.

Proven Cleaning Agent Performance: Field Evidence and Recovery Gains

D2132 cleaning agent case study: 23% average recovery uplift in offshore sandstone reservoirs

Take the D2132 cleaning agent as an example of what happens when good design meets real world conditions. Field tests across several offshore sandstone reservoirs showed something pretty impressive: around 23% more oil recovered overall. Why? Because this stuff works on two fronts at once lowering surface tension between fluids while also changing how rocks interact with water and oil. What's really nice is that it keeps performing well even under tough conditions. We're talking wells running anywhere from 1,500 up to 4,200 pounds per square inch pressure, and temps ranging between 60 and 85 degrees Celsius. Another big plus point: D2132 doesn't stick to quartz or clay surfaces much, which means injection rates stay strong over time without needing those expensive pre-treatment flushes that eat into budgets. All these features check off the boxes required by API RP 135 and ISO 10427 standards for enhanced oil recovery chemicals, but operators care more about actual performance than just meeting paper requirements.

Residual oil saturation control vs. environmental trade-offs: Balancing efficacy and sustainability

The push for aggressive interfacial tension reduction and wettability changes definitely boosts recovery rates, but we need to balance this with proper environmental care, particularly when working in delicate offshore areas. Many high performance surfactants such as D2132 have been tweaked recently to pass tough marine safety standards. They need to break down at least 60% within four weeks according to OECD test 301B, plus show minimal harm to brine shrimp at concentrations above 100 mg/L. More and more companies are switching to closed loop systems that separate phases during processing, which lets them recover and reuse around 95% of their chemicals. The benefits are huge - waste output drops by roughly 90% while staying ahead of new rules from groups like the International Maritime Organization regarding what chemicals can be used offshore, along with other regulations about harmful substances that stick around in the environment for years.

Maximizing Cleaning Agent Efficiency Through Process Integration

Ultrasound enhancement: Cavitation synergy with micelle formation at 20–40 kHz

When we combine low frequency ultrasound waves between 20 and 40 kHz with specially formulated cleaning solutions, something really interesting happens at the molecular level. The sound waves create tiny bubbles that pop and generate intense pressure spikes around 10,000 psi right next to surface pores. These popping bubbles physically break apart stubborn oil layers and help cleaning chemicals get deeper into narrow spaces much faster than just pouring them in. Tests show this method lets cleaning agents penetrate about 40 percent better compared to regular injection techniques. What's even more impressive is how this process lowers the tension between different substances down past 0.1 millinewtons per meter, which makes those microscopic oil particles start moving through tiny channels in the material. Real world testing has demonstrated that pairing ultrasound technology with D2132 cleaning solution can reduce leftover oil content by anywhere from 18 to 22 percent. Plus, since everything works at normal temperatures rather than requiring heat, the whole process uses roughly 30 percent less energy than traditional hot water extraction methods.

Oil-based mud waste treatment: Closed-loop oil reclamation (87% rate) using surfactant-based slurry wash

Cleaning solutions aren't just for keeping reservoirs productive anymore—they're playing a big role in handling waste from upstream operations too. When dealing with oil based mud waste, special surfactants mixed into slurry help separate hydrocarbons from solids much better than traditional methods. Field tests show this approach can pull out around 87% of oil from drill cuttings. What's really impressive is that the recovered crude actually passes important industry standards for density (ASTM D1298) and sulfur content (D4294) after just basic filtering. The system works well even when conditions get tough, handling pH levels between 4 and 10 and salt concentrations up to 200,000 ppm. That makes it suitable for almost any drilling site. On average, each treatment setup pulls about 500 barrels of sellable oil every day while cutting down on hazardous waste by nearly 95%. Companies save money too, with lifecycle costs coming in 40% below what they'd pay for sending waste to landfills or burning it offsite. So choosing the right cleaning agents isn't just good practice—it directly impacts bottom lines and environmental goals at the same time.

FAQ

What is the primary function of cleaning agents in crude oil recovery?

Cleaning agents lower the tension between oil and rock surfaces and alter wettability, making it easier to mobilize stuck crude oil and enhance recovery.

Why is hydrophilic-lipophilic balance (HLB) important for cleaning agents?

HLB is important because it helps create stable microemulsions, which is crucial for maintaining performance even when salt levels and temperatures fluctuate.

How does ultrasound enhance the efficiency of cleaning agents?

Ultrasound waves create tiny bubbles that generate intense pressure spikes to break apart oil layers, enhancing the penetration and effectiveness of cleaning agents.

What environmental considerations are associated with using cleaning agents?

Environmental considerations include ensuring cleaning agents break down rapidly and are minimally harmful, as well as implementing closed-loop systems to minimize waste.