Pozzolanic Cementing Additives: Building Long-Term Strength and Density

How silica fume, fly ash, and slag drive C-S-H formation and reduce permeability through secondary pozzolanic reactions

When added to cement mixtures, materials like silica fume, fly ash, and slag create something special through what's called secondary pozzolanic reactions. These materials react with calcium hydroxide CH that forms naturally during the hydration process of Portland cement, creating extra calcium silicate hydrate or C-S-H. What happens next is pretty remarkable. The new compounds fill in all those tiny spaces between particles in the cement matrix. This makes the whole structure much tighter, cutting down on water penetration by around 40 percent when compared to regular Portland cement alone. Silica fume works particularly well because its particles are super small about 100 times tinier than normal cement particles which helps pack everything together better and gets the important C-S-H forming sooner. Fly ash and GGBFS take longer to react but keep working over time, so they actually help build strength even after the standard 28 day mark. Together, these ingredients transform that soft, watery CH component into strong, load bearing C-S-H gel. This change makes concrete much tougher against problems we see in real world conditions like sulfates in soil, acidic waters, or pressure from underground fluids trying to seep through.

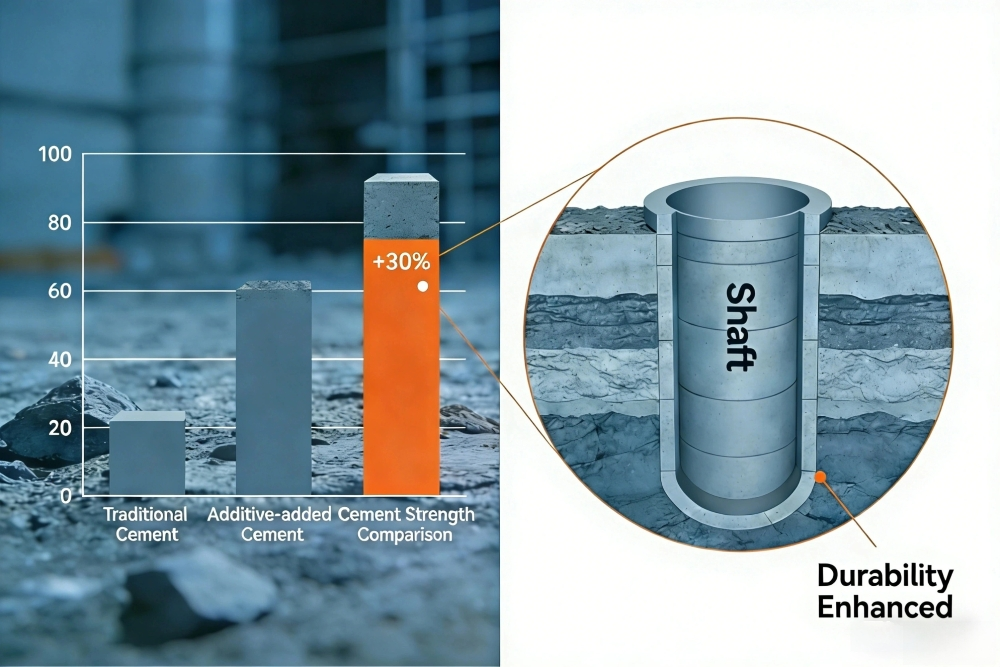

Real-world performance: 28-day strength gains (22–35%) and chloride diffusion reductions (up to 60%) in oilwell and marine-grade cement systems

Data collected both on site and in lab settings during offshore drilling operations and marine construction confirm these advantages. When silica fume is added to oil well cement mixtures, tests show around 25% improvement in compressive strength after 28 days compared to regular cement blends. This makes all the difference when dealing with intense pressures deep underground. For marine applications using Class F fly ash, we see about half reduction in chloride movement through the material. That means significantly less chance of steel reinforcement bars corroding in areas constantly exposed to seawater and salt spray. Blending slag with cement cuts gas permeability by roughly 40%, which helps stop unwanted gas migration between layers in wells. All these improvements come down to how these materials refine tiny pores within the concrete matrix while creating stronger bonding structures over time. For anyone building infrastructure near coastlines or in chemically aggressive environments, adding these special admixtures becomes absolutely necessary for getting decades of reliable service life out of their constructions.

Hydration-Accelerating Cementing Additives: Balancing Early Strength and Structural Integrity

Triethanolamine vs. tri-isopropanolamine: Kinetic effects on C-S hydration and 72-hour compressive strength optimization

Triethanolamine (TEA) and tri-isopropanolamine (TIPA) both speed up the hydration process of tricalcium silicate (C3S), but they work differently over time. TEA gets things moving fast from the start, which means concrete gains about 15 to 22 percent more strength after just 24 hours. That makes it great for projects needing quick turnaround or those working in chilly conditions where slower curing is a problem. TIPA takes a different approach altogether. Instead of rushing things initially, it keeps the acceleration going longer, so we see strength improvements of around 30% at the 72 hour mark. What's interesting about TIPA is how it interacts with the cement matrix itself. The way it sticks to surfaces creates denser C-S-H structures and better connections between particles, especially noticeable in mixes containing limestone. When carbonates are present in these blends, TIPA actually works even better than usual. Most contractors will tell you both additives play nicely with standard practices as long as they stay within the dosage ranges specified by ASTM C494 standards. Nobody wants unexpected set times or sudden hardening issues ruining a job site.

Strengthening the interfacial transition zone (ITZ) and suppressing microcracking via controlled hydration modulation

When we control the acceleration process, it actually improves what's called the interfacial transition zone, or ITZ for short. This area where cement paste meets aggregate has always been a weak spot in concrete structures. Accelerators help create more even growth of those important C-S-H crystals right at the boundary, cutting down on ITZ porosity somewhere around 40 to maybe even 50 percent. That makes the material much tougher against fractures and better bonded overall. What's really interesting is how this pore refinement spreads out stress more evenly throughout the material. Tests show that cracks start forming about 25% less frequently when materials go through thermal cycles according to ASTM standards. Getting the right amount of accelerator matters a lot too. Too much causes problems like hot spots or early stiffening, which messes up the paste consistency and stops those tiny microcracks from bridging properly. With proper control though, concrete stands up better to freezing and thawing cycles as well as repeated loads, all while maintaining good workability during placement and keeping stable dimensions over time.

Emerging and Specialty Cementing Additives for Targeted Durability Enhancement

Corrosion inhibitors (e.g., calcium nitrite) and nanomaterials (e.g., cellulose nanocrystals) for chloride resistance and crack-bridging functionality

Modern additive technologies tackle the root causes of material degradation rather than just treating symptoms. Take calcium nitrite for example, which has been recognized as a reliable corrosion inhibitor according to ASTM standards. This compound works by creating protective layers around steel reinforcements in concrete, transforming harmful ferrous ions into stable magnetite and hematite formations. Tests show it can cut down on chloride-related damage by roughly 70% in structures exposed to seawater environments. Alongside these chemical defenses, cellulose nanocrystals offer another layer of protection through physical means. These tiny rod-shaped particles measure between 5 to 20 nanometers in width and spread evenly throughout the cement mixture. They form bonds with the cement's hydration products and effectively bridge small cracks before they become structural issues. The combination of these approaches boosts bending strength by approximately 15 to 25%, while also enhancing how well materials hold up after cracking occurs. This matters a lot for things like bridges near coastlines or oil rigs out at sea where constant movement puts stress on construction materials. Before putting these specialized additives into actual projects though, engineers need to check how they interact with other common ingredients like fly ash or setting accelerators. Getting the mix right ensures that workability, air content, and curing times remain consistent with what was observed during lab testing.

FAQ

Q: What are secondary pozzolanic reactions?

A: Secondary pozzolanic reactions occur when materials like silica fume, fly ash, and slag react with calcium hydroxide during the hydration process of Portland cement, leading to additional formation of calcium silicate hydrate (C-S-H), which strengthens the cement matrix and reduces permeability.

Q: How do hydration-accelerating additives like TEA and TIPA affect concrete curing?

A: Triethanolamine (TEA) speeds up hydration early, aiding quick strength gain within 24 hours, whereas tri-isopropanolamine (TIPA) sustains acceleration over a longer period, enhancing strength at the 72-hour mark.

Q: What role do corrosion inhibitors and nanomaterials play in concrete?

A: Corrosion inhibitors like calcium nitrite prevent damage by protecting steel reinforcements, while nanomaterials such as cellulose nanocrystals strengthen concrete by bridging cracks and forming bonds with hydration products.