Understanding Shale Swelling and Its Drilling Challenges

Why shale swelling is a problem

When water based drilling fluids come into contact with certain types of reactive clay minerals, shale swelling happens as these minerals absorb moisture and expand in volume. The result? Wellbore diameters can shrink by around 15 percent or so, creating serious stability problems downhole. What typically follows are several costly complications. Stuck pipe situations alone account for roughly 40 percent of all non productive time during drilling operations. Then there's bit balling, where cuttings stick to the drill bit surface, slowing down progress by anywhere from 30 to 50 percent. All these challenges drive up expenses dramatically while also posing real safety concerns. That's why proper shale inhibition techniques remain absolutely critical if companies want their drilling operations to run both efficiently and safely.

Clay mineral composition and reactivity in shale formations

Shale tends to swell quite a bit, and this mainly comes down to what kind of clay minerals it contains. Smectite minerals stand out because they have really high cation exchange capacity (CEC) and can actually expand between 200 and 300 percent when water gets into them thanks to their special lattice structure that allows expansion. Then there's illite and those mixed layer clays too. These aren't as aggressive as smectite, but they still cause problems for stability issues in formations. When looking at CEC values, anything over 25 meq per 100 grams means we're dealing with highly reactive materials here, so proper inhibition becomes absolutely critical. Because of all this variation from one formation to another, effective shale management isn't just about applying standard inhibitors. Instead, engineers need to match the chemical treatment specifically to whatever minerals happen to be present in each particular geological setting.

Wellbore instability caused by shale swelling

When shale swells, it really messes with the integrity of the wellbore through several different failure paths. The worst case scenario happens when the well collapses entirely. Expanded shale basically cracks apart and tumbles down into the hole. This leads to what's called stuck pipe situations. Operators know all too well how expensive these incidents get. Industry reports suggest each stuck pipe event typically costs around $1.2 million on average. There are other problems too. Shale sloughing causes the hole diameter to increase over time. This creates all sorts of irregular shapes inside the wellbore that make casing and cementing operations a real headache. All these stability issues together eat up about 20% of non-productive time during drilling operations. That's why smart operators focus so much attention on preventing shale expansion right from the start. It makes sense both economically and operationally for keeping things running smoothly and safely underground.

Chemical Mechanisms of Shale Inhibitor Action

Cation Exchange and Potassium Chloride Effect on Shale Hydration

The oil and gas industry relies heavily on potassium chloride (KCl) to stop shale from expanding during drilling operations. This works through what's called cation exchange, basically swapping out sodium ions (Na+) on clay surfaces with potassium ions (K+). Why does this work so well? Well, potassium ions are smaller and don't hold onto water molecules as tightly as sodium does. When they take over those clay surface spots, the whole structure becomes more stable. Water just doesn't get absorbed into the clay layers as much, which prevents that annoying expansion problem. Field tests have demonstrated something pretty impressive too. Using around 3 to 7 percent KCl solutions can cut down shale swelling by nearly three quarters when compared to regular freshwater treatments. For operators dealing with challenging formations, this represents both an economical solution and one that stands up under tough conditions across various drilling scenarios.

Dehydration of Clay Surfaces Through Chemical Inhibition

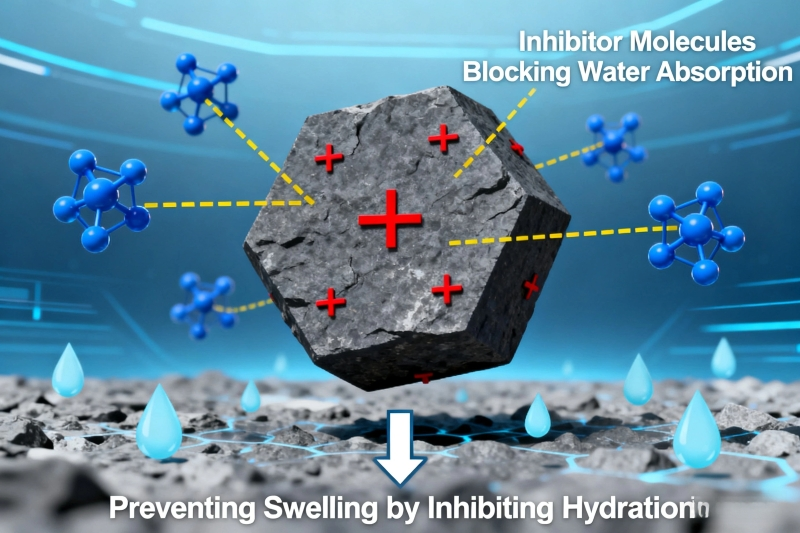

Clay surface dehydration happens when advanced inhibitors stick to these surfaces through electrostatic forces and hydrogen bonds, pushing out the water molecules trapped between layers. The result? Less space between layers and reduced swelling pressure. Industry tests show some products can cut linear swelling by as much as 80%, though results vary depending on conditions. This approach works best in situations where regular osmotic control methods fall short, making it a valuable tool for challenging geological formations that resist traditional treatment approaches.

Reduction of Water Permeation Rate Into Shale

Inhibitors designed for high performance work by creating both physical and chemical defenses inside the shale formation. These materials thicken the fluids and seal off tiny pores, which cuts down on water movement through the rock. Lab tests show water transmission can drop anywhere from 60 to 85 percent when these inhibitors are properly applied. What really works best in practice is a combination approach that includes things like cation exchange processes, surface sticking properties, and actual pore plugging. This layered defense system helps protect against unwanted hydration effects and keeps the wellbore stable during operations.

Osmotic Regulation and Polymer-Based Encapsulation

Osmotic transfer and water activity in shale inhibition

The principle behind osmotic inhibition involves changing the salt content in drilling fluids to establish a proper water activity gradient. If the drilling mud contains more salt than what's present in the shale pores, osmotic forces will push water away from the rock formation. This process dries out the clay minerals within the shale, stopping them from expanding. Getting this right matters a lot when it comes to keeping wells stable. Water sensitive shales can collapse or break down if they absorb too much moisture, which leads to serious problems during drilling operations. That's why many operators focus so much attention on managing these salinity levels properly in their field work.

Role of polyalkylene glycols (PAGs) in maintaining osmotic balance

Polyalkylene glycols, or PAGs as they're commonly called, work their magic by creating what amounts to a partial barrier between the shale and surrounding fluids. This allows excess water to escape from the formation while keeping unwanted fluids out. What makes these water soluble polymers so useful is that they boost how well we can prevent damage, all while cutting down on the need for those high salt solutions that can be problematic. A recent study looking at drilling fluids back in 2023 showed something pretty impressive too. Systems using PAGs cut down shale swelling issues by around 40 percent when compared with traditional methods. That kind of performance makes them particularly attractive option for operations in places where environmental concerns are front of mind.

Encapsulation using polymers like PHPA

Partially hydrolyzed polyacrylamide, commonly known as PHPA, works by creating a sort of mechanical shield around shale cuttings. It forms a protective polymer layer that keeps these cuttings away from direct water contact which would otherwise cause them to disperse. The result? Better handling of cuttings during drilling operations and overall improvement in maintaining clean wellbores. Looking at actual field data from deepwater projects, operators have observed something quite significant. When using PHPA systems, there's about a 35 percent reduction in problems related to wellbore cleaning. Plus, these systems help cut down on those frustrating periods of non-productive time that typically arise when dealing with unstable shale formations.

Hydrophobic modification of materials for shale stabilization

Hydrophobic treatments alter clay surface chemistry to repel water, minimizing fluid invasion into micro-fractures. By reducing capillary pressure and water adsorption, these modifications provide long-term stabilization. A 2022 study found hydrophobic inhibitors reduced shale permeability by 50% compared to untreated samples, offering a durable alternative to osmotic-only approaches.

Evaluating Shale Inhibitor Performance in the Lab and Field

Laboratory testing techniques for inhibitor performance

Testing in lab settings remains key when evaluating how well shale inhibitors work under conditions similar to those deep underground. The usual approach involves hot rolling tests that look at how much cuttings come back intact, plus linear swell measurements that track how shale samples expand or contract. By running these various tests side by side, engineers get a clear picture of which fluids perform best under different scenarios involving temperature variations and pressure levels. This kind of data helps companies tweak their fluid recipes until they find something that works reliably in actual drilling operations.

Rolling dispersion tests and linear swelling measurements

When testing shale cuttings for stability after contact with drilling fluids, rolling dispersion tests give us important information about how well they hold together. If the recovery rate stays above 90%, that's generally seen as good inhibition performance. For another angle on this issue, linear swelling measurements show just how much expansion happens over time. The best inhibitors can cut down on this swelling by around 70 to 85 percent when compared against regular water based fluids that haven't been treated. By combining results from both these approaches, engineers get a pretty complete picture of what's happening mechanically and chemically within the formation during drilling operations.

Case Study: Field application of PHPA in deepwater drilling

During a deepwater drilling project where reactive shale formations were encountered around 12,500 feet downhole, operators put into use a PHPA based inhibitor that had shown impressive results in lab conditions with about 94% cutting recovery rates. What happened next was pretty remarkable actually the field performance matched what had been seen in those controlled experiments. There was roughly a 40 percent drop off in problems related to wellbore instability, plus non productive time dropped by nearly 22% when compared against similar wells that stuck with traditional inhibitors. These real world results really back up what many engineers have long suspected but couldn't prove definitively before proper testing methods make all the difference between theory and actual field success.

Strategy: Selecting the right inhibitor based on shale reactivity

Getting good inhibition results means pairing the right chemistry with what's actually happening downhole in the formation. For those high smectite shales where the CEC levels run high, potassium based inhibitors tend to work best. When dealing with formations that are mechanically weak or have lots of fractures though, polymer encapsulators such as PHPA generally give better performance. Field tests over recent years show these targeted approaches make a real difference. Drilling operations see around a 30% boost in efficiency when using this method, plus there's typically between half and two thirds less downtime caused by issues related to drilling fluids. That beats the old one size fits all methods hands down in most cases.

Emerging Trends and Industry Challenges in Shale Inhibitor Use

Many industries are turning to cationic surfactants including DTAC and CTAB because they work really well at adsorbing clay and inhibiting problems. The catch? These chemicals can be pretty harmful to the environment since they don't break down easily and are toxic, particularly in areas where ecosystems are fragile. Because of this concern, researchers and manufacturers have started looking for greener options. Some promising alternatives include certain high molecular weight polyamino acids and modified starch products. These newer materials seem to perform almost as well as the traditional ones while causing far less damage to the environment. Companies now need solutions that meet both performance standards and environmental regulations, making sustainability not just a buzzword but an actual business requirement.

Frequently Asked Questions (FAQ)

What is shale swelling?

Shale swelling occurs when water-based drilling fluids react with clay minerals in the shale, causing these minerals to absorb moisture and expand in volume.

Why is shale swelling a significant issue in drilling?

Shale swelling reduces wellbore diameters, causing stability issues and non-productive time due to complications such as stuck pipe situations and bit balling.

How can shale swelling be prevented?

Preventing shale swelling involves using chemical inhibitors, such as potassium chloride for cation exchange, dehydration agents, and advanced inhibitors to stabilize wellbores.

What are the new trends in shale inhibitor use?

Emerging trends focus on eco-friendly inhibitors, such as high molecular weight polyamino acids and modified starch products, to reduce environmental harm while maintaining inhibitor effectiveness.

Table of Contents

- Understanding Shale Swelling and Its Drilling Challenges

- Chemical Mechanisms of Shale Inhibitor Action

- Osmotic Regulation and Polymer-Based Encapsulation

- Evaluating Shale Inhibitor Performance in the Lab and Field

- Emerging Trends and Industry Challenges in Shale Inhibitor Use

- Frequently Asked Questions (FAQ)