Ensuring Well Integrity with Effective Cementing Additives

How Cementing Additives Contribute to Long-Term Well Integrity

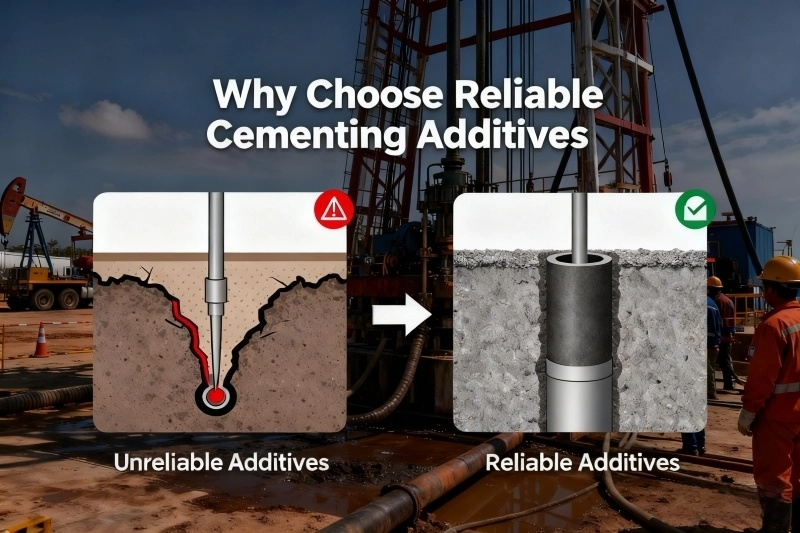

Additives used in cementing operations really boost how well the slurry performs when exposed to harsh downhole conditions, helping it hold together for many years without breaking down. These special compounds work in several ways: they control fluid loss from the mix, stop gases from moving through the formation, and actually make the final product stronger so it can handle compression forces better. What's more, they create a cement sheath that stands up against both physical stresses and chemical attacks from corrosive substances in the well. Dispersants play their part too by making sure everything mixes evenly throughout the slurry, which reduces those pesky voids that weaken the barrier between different zones in the wellbore. Then there are these crystalline additives that do something pretty cool - they actively plug up tiny cracks that start forming under pressure. According to research published in 2025, wells treated with these advanced additive combinations maintained around 98% effectiveness in keeping zones isolated after ten whole years underground. That's way better than what we typically see with older methods, where only about 76% of wells kept their isolation properties intact over the same period.

Zonal Isolation as a Critical Outcome of Effective Cementing

Good zonal isolation stops unwanted fluid movement between different geological layers, which helps protect the environment and meet all those pesky regulations. Expansion agents help create strong bonds between the casing and surrounding rock formations. Meanwhile, adding lightweight materials keeps cement slurries stable when dealing with tricky porous areas or weaker sections of the formation. Looking at data from recent industry reports, wells using properly formulated cement mixes saw around a 40% drop in sustained casing pressure problems in hot reservoir conditions. This shows how important these specialized additives are for keeping wells safe over their entire lifespan.

Case Study: Improved Well Integrity Using Fluid Loss Control Additives

Operators working in the Middle East faced serious issues with fluid loss running over 30 barrels per hour when dealing with fractured limestone formations. When they started using polymer based additives for controlling fluid loss, things changed dramatically. The losses dropped down to just 4 barrels per hour, which allowed full coverage around the casing. Looking at post cement evaluations revealed something remarkable too. The bond index improved by about 92%, so there was no longer any need for expensive remedial squeeze cement jobs. That saved roughly $2.7 million per well according to estimates. These results back up what many in the field already know from experience. Good quality fluid loss additives can cut down cement permeability anywhere between 60-80% when compared against regular untreated mixtures.

Strategy for Selecting Additives That Enhance Zonal Isolation and Durability

Selecting the right additives requires addressing site-specific challenges:

- Temperature compatibility: Use retarders in high-temperature formations (>200°F)

- Salt resistance: Incorporate supplementary cementitious materials (SCMs) like fly ash in saline environments

-

Flexibility: Apply elastic modifiers in shale plays subject to cyclic loading

Laboratory testing under simulated downhole conditions remains critical—improper additive dosing was linked to 37% of cement failures in a 2024 API audit.

Optimizing Cement Slurry Performance Through Advanced Additive Technology

Understanding Slurry Rheology and Its Dependence on Cementing Additives

The way slurry flows has a major impact on how well it can be pumped and placed where needed. These days, we're seeing all sorts of advanced additives hitting the market that help control things like shear stress and viscosity so the slurry keeps flowing properly even when subjected to those intense downhole pressures. Take hydroxypropyl methylcellulose (HPMC) for instance. Field tests show this stuff cuts water bleeding rates by around 60% compared to old school bentonite treatments, plus it gives better hydration stability too according to research published in Powder Technology back in 2025. Getting the right mix of additives really matters because it makes sure the slurry spreads out evenly throughout the formation. Without proper distribution, we end up with gaps or voids in the cement job, which nobody wants since those spaces can compromise zonal isolation and lead to serious problems later on.

Workability and Setting Time Control Using Retarders and Accelerators

Cement setting times can be finely controlled using retarders and accelerators depending on temperature conditions during operations. When working in hot environments above 150 degrees Celsius, retarders help maintain workable consistency for longer periods. For those dealing with shallower wells where temperatures are lower, calcium chloride based accelerators typically cut down setting time anywhere between 35 to maybe even 50 percent according to what most field tests show about viscosity changes. Having these adjustable options means field crews can better match when concrete gains strength with their actual project schedules on site.

Performance Benefits of Chemical Admixtures in Dynamic Well Environments

In deviated or HPHT wells, polymer-based dispersants and gas migration inhibitors mitigate mechanical stresses during placement. Recent field trials show:

| Additive Type | Friction Reduction | Gas Migration Risk |

|---|---|---|

| Superplasticizers | 28% | 41% |

| Latex Polymers | 19% | 68% |

These admixtures enhance slurry cohesion during turbulent flow, reducing the likelihood of channeling and remedial interventions. Their use has been associated with average savings of $210k per well in repair costs (Ponemon 2024).

Data Insight: Impact of Superplasticizers on Cement Slurry Performance

Superplasticizers improve particle dispersion, allowing 18–22% lower water-cement ratios without sacrificing workability. Field data from 23 Gulf of Mexico wells confirm they increase 24-hour compressive strength by 14 MPa—an important factor for early well integrity. When combined with SCM-enhanced formulations, superplasticizers reduce permeability risks by 33% in corrosive environments.

Enhancing Durability and Strength with Proven Cementing Additives

Improving Concrete Workability and Strength with Additives

The latest generation of additives makes a real difference in how concrete works and holds up over time. According to recent research published in Cement Chemistry last year, certain polymer additives actually reinforce those calcium silicate hydrate structures inside concrete, which means stronger compression resistance (around 30% to 40% better) and fewer tiny cracks forming. Silica dioxide nanoparticles are another game changer. They pack into the cement mixture so tightly that it becomes much denser. This property is why engineers love using these materials for projects under intense pressure conditions like underwater oil platforms or deep underground tunnels where traditional concrete just wouldn't cut it.

Role of Supplementary Cementitious Materials (SCMs) in Strength Development

Supplementary cementitious materials such as fly ash and slag cement actually work with leftover lime in cured concrete to boost its strength over time and make it last longer. According to recent research published in Frontiers in Built Environment last year, blends containing these materials can reach impressive 28 day compressive strengths around 94.8 MPa, which is about 40 percent better than what we typically see from regular concrete mixes. Plus, they cut down on carbon emissions significantly, saving approximately 338 kilograms per cubic meter. For construction projects where structural integrity matters alongside environmental impact, incorporating SCMs into the mix design becomes essential rather than optional.

Use of Calcined Clays and Pozzolans in Concrete for Enhanced Durability

When it comes to chemical resistance, calcined clays and natural pozzolans work wonders by filling those tiny capillary pores and neutralizing harmful reactive substances. Tests show these materials cut down chloride ion penetration around 35 percent in coastal areas where saltwater is a constant threat. For oil wells, they stand up against sulfate attacks that can weaken casing structures over time. This means infrastructure lasts much longer than usual sometimes adding decades to its useful life. Plus, since these materials are produced with significantly lower carbon emissions compared to traditional alternatives, they fit right into today's push for greener building practices across the construction industry.

Balancing Cost-Effectiveness and Long-Term Value in Additive Selection

Initial Cost vs. Lifecycle Savings in Well Construction Projects

Cheap additives might cut upfront capital expenses by around 15 to 20 percent, but better quality options usually pay off in the long run thanks to their reliability and need for fewer fixes down the line. Looking at data from oil wells in the Gulf of Mexico back in 2023, companies that invested in these advanced gas migration control additives saw their maintenance bills drop by nearly a third over five years when compared to folks sticking with basic formulas. The latest Material Performance Report from 2024 makes it clear why this matters so much. When picking additives, factors like how stable they stay under pressure and whether they work well during later stages of oil extraction really impact bottom line results. Smart operators know this stuff matters beyond just price tags.

Controversy Analysis: Cheap Additives Leading to Costly Remediation

Cheap, unstable extenders keep causing problems especially when exposed to repeated temperature changes. Remember that big mess in 2022 where they had to spend nearly $18 million fixing a well? Turns out it all came down to those cheap extenders breaking down over time. The fix could have cost just around $280,000 if they'd gone with something built to handle heat instead. Looking at Baker Hughes numbers from last year shows most money spent on fixes comes from bad additive decisions. About 40% of operators still go for the cheapest option first even though it costs them later. Makes sense why companies are pushing for better testing standards now. We need protocols that actually mimic what happens deep underground before signing off on purchases.

Sustainable Cementing Solutions: Environmental Benefits of Modern Additives

Cement additives reducing carbon emissions through SCMs

Studies published in Frontiers in Materials back up what many industry experts have been saying for years: using things like fly ash and slag as supplementary cement materials cuts down on the carbon footprint of cement mixtures by around 25 to 40 percent compared with regular concrete blends. What makes this even better is that these materials are actually waste products from other industries. Instead of ending up in landfills where they would sit around doing nothing, we're putting them to good use in construction projects. The numbers tell an interesting story too – over 15 million metric tons of this material gets diverted from landfills every year through these practices. And here's another benefit nobody wants to overlook: the final product maintains all its strength properties despite incorporating these recycled components, which means no sacrifice in quality when going green.

Environmental advantages of low-carbon cement formulations

Low-carbon cement formulations minimize clinker content—the primary source of CO₂ emissions in production—while maintaining durability. Third-party assessments show these blends reduce CO₂ output by 30–50% per well. Additives that enhance calcined clay reactivity further boost performance, enabling reliable zonal isolation even in high-temperature applications.

Industry trend: Growing adoption of sustainable cementing solutions

When it comes to designing cement these days, sustainability has become pretty much essential. About three out of four drillers across North America are asking for low carbon cement options when they start up new wells. Why? Well, regulations keep getting tighter, companies want better ESG scores, and folks are starting to see real money savings down the road. The thing about sustainable additives is they cut down on emissions for sure, but there's another benefit too. They actually reduce the chances of needing expensive fixes later on. So what we get here is a win-win situation where protecting the environment goes hand in hand with saving costs in the long run.

FAQ Section

What are cementing additives?

Cementing additives are compounds added to cement slurries to enhance their properties and performance in wells, specifically to boost long-term integrity, control fluid loss, and ensure effective zonal isolation.

How do cementing additives contribute to well integrity?

Cementing additives contribute to well integrity by strengthening the cement structure, reducing permeability, and preventing gas migration, which ensures that different zones remain isolated and protected from environmental and regulatory pressures.

What is the role of supplementary cementitious materials (SCMs) in cementing?

Supplementary cementitious materials (SCMs) like fly ash and slag cement enhance the strength development and durability of cement over time while also reducing the carbon footprint of the mixture.

Why is sustainability important in cementing solutions?

Sustainability is crucial in cementing solutions because it reduces the carbon footprint, diverts waste from landfills, decreases the need for costly repairs, and supports better environmental and economic outcomes for construction projects.

Table of Contents

- Ensuring Well Integrity with Effective Cementing Additives

- Optimizing Cement Slurry Performance Through Advanced Additive Technology

- Enhancing Durability and Strength with Proven Cementing Additives

- Balancing Cost-Effectiveness and Long-Term Value in Additive Selection

- Sustainable Cementing Solutions: Environmental Benefits of Modern Additives

- FAQ Section