Understanding H2S and Mercaptans in Hydrocarbon Systems

The Presence of H2S and Mercaptans in Crude Oil and Natural Gas

Hydrogen sulfide (H2S) along with various mercaptans can be found naturally in around 78 percent of all crude oil deposits and about 65% of natural gas fields. They form when microorganisms break down organic materials or through processes involving heat breaking molecular bonds. These sulfur based chemicals tend to mix easily into hydrocarbon flows. Sour crude oils frequently contain H2S levels above 50 parts per million, which makes them particularly problematic for processing plants. As for mercaptans, these compounds have those telltale thiol groups we talk about so much in chemistry classes. Their presence ranges from roughly 10 to maybe even 200 ppm depending largely on what kind of rock formations they're sitting in underground.

Toxicity, Odor, and Corrosion Risks Associated with H2S Mercaptan Scavenger Applications

Exposure to hydrogen sulfide can be deadly even at 100 parts per million concentration levels. Mercaptans are another story entirely though they're still pretty potent stuff. We can actually smell them at around 10 parts per billion which is roughly like finding one single drop of liquid in an entire Olympic sized swimming pool. These compounds really eat away at pipeline materials too. They speed up corrosion processes somewhere between 20 to 40 percent because of acid formation, and this causes serious problems for midstream operators who end up spending approximately 740 thousand dollars every year just fixing unexpected maintenance issues according to Ponemon's research from last year. Recent safety studies also show that when companies don't handle H2S properly, workers face significantly higher risks on site. The danger level jumps eight times what it normally would be compared to working with sweet crude oil instead.

Impact on Downstream Processing and Product Quality

When H2S isn't properly scavenged during processing, it eats away at refining catalysts at a rate that's anywhere from 30 to 50 percent faster than normal wear and tear would typically allow, which really cuts down on how much throughput we can get out of our systems. Then there's the issue with mercaptans ending up in finished fuels. These compounds knock octane ratings down by about 2 to 3 points and run afoul of those EPA regulations regarding sulfur content limits, specifically the 15 parts per million threshold that just won't be crossed without serious penalties. Over in petrochemical production areas, all these unwanted contaminants create problems with polymerization processes too. What happens is quite simple actually - when things don't go as planned during polymerization, we end up with significantly more off-spec products each year. Industry reports suggest somewhere between 12 and 18 percent increase in such problematic outputs across most North American plants dealing with these issues.

Types of H2S Mercaptan Scavenger Technologies and Their Mechanisms

Triazine-Based H2S Mercaptan Scavenger: Mechanism and Efficiency

Triazine based formulations work by binding hydrogen sulfide molecules via nucleophilic addition reactions, transforming the dangerous H2S gas into stable trithiane compounds that won't evaporate easily. Field tests show these chemical scavengers can remove around 95 percent of hydrogen sulfide from gas streams when temperatures stay under 93 degrees Celsius or 200 Fahrenheit. This makes them particularly useful in natural gas processing plants and oil refineries where H2S control is critical. Industry testing has confirmed they cut down mercaptan concentrations to between 10 and 15 parts per million, which is impressive considering they still work well alongside existing amine treatment systems without causing any compatibility issues.

Non-Triazine Alternatives: Oxidation and Absorption Pathways

Metal based scavengers and those containing nitro compounds work through redox reactions that convert hydrogen sulfide (H2S) into either elemental sulfur or sulfate byproducts. Take iron oxide pellets as an example they can remove about 80 to 90 percent of H2S from sour crude oil pipelines via chemisorption processes. These materials have advantages over traditional triazine chemistry options since they don't suffer from pH related issues and function well even when temperatures go above 150 degrees Celsius. The catch is that operators need to maintain just the right balance between oxygen and H2S levels to prevent problems with iron sulfide scaling on equipment surfaces.

Water-Soluble vs. Oil-Soluble H2S Mercaptan Scavenger Formulations

In water treatment processes, water soluble scavengers such as MEA triazine are commonly used because they spread quickly through water based solutions. For instance, they work great in treating produced water from oil operations. On the other hand, oil soluble versions made with alkylated amines tackle hydrogen sulfide specifically in places where there's lots of hydrocarbons or thick crude oil. Recent research from last year showed something interesting about these oil soluble systems. They managed to cut down hydrogen sulfide levels by around 92% in those tough high TAN crude situations. What makes them even better is that they beat their water based counterparts by about 18% when dealing with really thick fluids, which matters a lot in real world applications.

Regenerative vs Non-Regenerative Scavengers: Long-Term Operational Impact

Zinc oxide absorbers fall into the category of regenerative tech that can be reused about five to seven times before needing replacement, which brings down chemical costs around 40 percent when compared with those one-time triazine options. The thing is, most high volume systems still stick with non-regenerative scavengers because they work predictably and are easier to set up in practice. According to industry reports, these traditional systems manage to remove nearly all hydrogen sulfide from gas streams at processing facilities, hitting that 99.9% mark consistently. But there's a tradeoff here too many plants end up producing somewhere between 30 and 50 percent more waste chemicals each year than what would happen with regenerative alternatives.

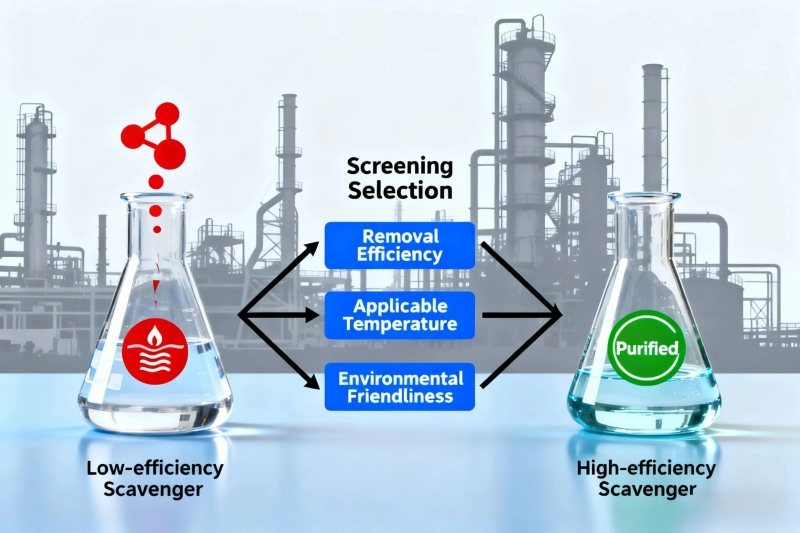

Key Factors in Selecting the Right H2S Mercaptan Scavenger

H2S Concentration Levels and Required Scavenging Capacity

The effectiveness of treatment is closely tied to how much sulfide is present in the system. When hydrogen sulfide concentrations go above 200 parts per million, the scavengers need to work at least 90 percent efficiently just to pass pipeline standards. Finding the right dosage balance is tricky business for plant operators. If they don't put enough scavenger into the mix, dangerous gas remains in the system. But throw in too much and chemical expenses jump anywhere from 15 to 40 percent higher based on what we've seen in actual operations across the industry. That's why many facilities now rely on continuous monitoring equipment working hand in hand with automated injection systems. These setups help adjust chemical usage dynamically as sour gas levels change throughout the day, keeping both safety and budget constraints in check.

Operating Temperature and Pressure Effects on Scavenger Performance

Triazine-based formulations lose 35% efficiency at temperatures above 140°F due to accelerated thermal degradation, while metal-based scavengers demonstrate stable performance up to 320°F. High-pressure systems (>1,500 psi) favor non-regenerative scavengers with rapid reaction kinetics to prevent H2S breakthrough during compression cycles.

Solubility and Phase Compatibility in Multiphase Hydrocarbon Streams

Water-soluble scavengers dominate gas processing with <2% liquid hydrocarbon content, whereas oil-soluble variants prevent emulsion formation in crude streams containing 15–30% brine. Phase partitioning tests should confirm <5% scavenger carryover into undesired phases to maintain cost-effectiveness.

Chemical Composition of Feedstock and Potential Interferences

Mercaptan-rich feedstocks (>500 ppm RSH) require scavengers with dual H2S/mercaptan affinity to prevent fouling in glycol contactors. Amine-based systems show 20–50% reduced efficiency when exposed to oxygenated contaminants, necessitating pre-treatment filtration for streams containing >10 ppm dissolved O².

Performance Comparison: Triazine-Based vs. Non-Triazine H2S Mercaptan Scavengers

Reaction Mechanisms: Chemical Binding vs. Redox Transformation

Triazine based scavengers work by chemically binding with hydrogen sulfide through what's called nucleophilic addition reactions. This process turns the harmful gas into harmless trisulfide compounds. For those looking for options outside triazine, there are non-triazine solutions such as nitrates that function differently. These alternatives rely on redox reactions instead, basically taking H2S and turning it into either elemental sulfur or sulfate compounds. According to the latest Scavenger Efficiency Report from 2024, triazine systems manage about 95% removal of hydrogen sulfide when temperatures are around room level (about 25 degrees Celsius). However, things get tricky when temps rise past 80 degrees Celsius because the material starts breaking down thermally, which knocks about 12% off its effectiveness. Redox based systems tell a different story though they keep performing pretty well even in hotter conditions, maintaining over 88% efficiency across much broader temperature ranges than their triazine counterparts.

Removal Efficiency Under Varying Field Conditions

| Factor | Triazine Performance | Non-Triazine Performance |

|---|---|---|

| Low H2S (<50 ppm) | 92–97% removal | 85–92% removal |

| High Salinity | Reduced solubility | Stable phase dispersion |

| Multiphase Systems | Requires mixing | Oil-soluble variants available |

Field trials in shale gas operations show triazine requires 20% higher dosage than non-triazine options to achieve equivalent H2S reduction in high-flow conditions.

Byproduct Formation and Equipment Implications

When triazine reacts, it creates these trisulfide salts that tend to form deposits inside pipelines. This actually raises the scaling problem by around 18% in areas where there's lots of calcium present. The other option, non-triazine redox systems, does create acidic stuff as waste products so they need careful pH management. But at least they don't leave behind those solid deposits that clog things up. Either way, keeping an eye on corrosion is important. For triazine systems, the pipe walls wear down about 0.03 mm each year. Compare that to nitrate based options which erode pipes at roughly 0.05 mm per year in those sour gas environments. Makes quite a difference when looking at long term maintenance costs.

Cost-Benefit Analysis of Sustained Use

While triazine costs $1.20/lb compared to $1.50/lb for advanced non-triazine scavengers, operational savings emerge in high-volume applications:

- 30% lower dosage requirements for non-triazine systems

- 50% reduced waste disposal costs due to water-soluble byproducts

A 5-year industry analysis shows total ownership costs for triazine average $740k versus $620k for optimized non-triazine deployments, justifying upfront investment in next-generation formulations.

Operational and Environmental Considerations in H2S Mercaptan Scavenger Deployment

Impact on Corrosion Prevention Strategies

H2S scavengers work against corrosion problems by getting rid of hydrogen sulfide, which is one of the main causes of sulfide stress cracking in both pipelines and storage tanks. Studies indicate that these products can cut down on maintenance expenses by around 40 percent in sour gas systems when they bring H2S levels down to under 10 parts per million. Different types of scavengers perform differently chemically speaking. The ones based on triazines tend to produce stable thiadiazine compounds as leftovers, whereas other options not containing triazines, such as various metal carboxylates, leave behind materials that aren't so corrosive. When choosing what kind of scavenger to use, operators need to think about the type of metal involved too. For instance, certain amine-based products might actually speed up pitting issues in carbon steel equipment when operated at elevated temperatures.

Chemical Compatibility with Pipelines, Separators, and Treatment Units

For scavenger formulations to work properly, they need to stay soluble in all three main phases found in production environments gas, crude oil, and produced water. Otherwise, we end up with fouling problems down the line. The water soluble types like those sodium hydroxide mixes tend to create emulsions when flowing through multiple phases at once. On the flip side, oil soluble options might actually damage the rubber seals inside processing equipment over time. Looking at actual field results, operators see around a quarter drop in efficiency whenever temps go above 120 degrees Celsius because the active components start breaking down thermally. And don't forget about compatibility tests with those pipeline additives used for flow assurance either. When these substances don't play nice together, they often result in thick sludge buildup inside separators that nobody wants to deal with during maintenance checks.

Environmental Footprint and Regulatory Compliance Challenges

Regenerative scavengers cut down on waste production by about 60 to 70 percent when compared with their single use counterparts. However these systems need quite a bit of energy for the reactivation process which can be costly. The non regenerative alternatives such as zinc oxide slurries are running into problems with disposal rules because they contain heavy metals. The Environmental Protection Agency released new guidelines back in 2023 that limit how much zinc can be discharged into offshore waters to just 2 parts per million. Research published last year showed that triazine based compounds actually raise biochemical oxygen demand levels in wastewater treatment plants by around 35 percent, making it harder to get those necessary discharge permits approved. Because of all these factors, many facility managers are turning towards ISO 14001 certified scavenger products that break down naturally over 80 percent of the time, helping them stay compliant with international green standards while still maintaining operational efficiency.

FAQ Section

What are mercaptans found in crude oil?

Mercaptans in crude oil are sulfur-containing compounds with detectible odors that can be corrosive and are typically monitored due to their chemical properties.

What is the danger of H2S exposure?

Exposure to H2S is dangerous and potentially deadly even at low concentrations, starting around 100 parts per million, due to its toxic nature.

Why is H2S removal important in processing plants?

Removing H2S is crucial because it accelerates corrosion, degrades refining catalysts, and violates product specifications on sulfur content, affecting both safety and product quality.

How do triazine-based scavengers work?

Triazine-based scavengers work by chemically binding hydrogen sulfide into stable byproducts, effectively reducing its concentration and associated risks in process streams.

Are non-triazine scavengers more environmentally friendly?

Non-triazine scavengers can be more environmentally friendly by producing fewer solid deposits and sometimes having operational advantages like broader effective temperature ranges.

Table of Contents

- Understanding H2S and Mercaptans in Hydrocarbon Systems

- Types of H2S Mercaptan Scavenger Technologies and Their Mechanisms

- Key Factors in Selecting the Right H2S Mercaptan Scavenger

- Performance Comparison: Triazine-Based vs. Non-Triazine H2S Mercaptan Scavengers

- Operational and Environmental Considerations in H2S Mercaptan Scavenger Deployment

- FAQ Section