Enhanced Engine Performance Through Cleaner Combustion

How Fuel Additives Improve Engine Performance Through Optimized Combustion

Quality fuel additives enhance the air-fuel mixture's combustion efficiency, promoting more complete diesel burn. This reduces unburned fuel residues while increasing energy output per cycle. Detergents in additives prevent carbon buildup on injectors, preserving precise spray patterns and optimal combustion chamber performance.

Deposit Control in Diesel Fuel Systems Prevents Power Loss and Maintains Efficiency

Deposit-control agents in modern additives dissolve existing contaminants and inhibit new deposits. In high-pressure common rail systems, even minor injector fouling can reduce power output by 4–7%. By keeping fuel lines and injectors clean, additives maintain factory-specified flow rates and prevent efficiency loss.

Cetane Number Improvement Enhances Ignition Quality and Cold Startability

Premium additives boost cetane ratings by 3–8 points, improving ignition timing consistency. Higher cetane reduces ignition delay in compression-ignition engines—especially critical in cold climates where untreated diesel struggles to vaporize. Fleet operators report up to 40% faster cold starts at -20°C using cetane-enhanced fuels.

Case Study: Improved Engine Responsiveness in Long-Haul Truck Fleets Using Performance Additives

A 12-month trial with 150 Class 8 trucks demonstrated clear benefits from additive use:

| Metric | Improvement |

|---|---|

| Acceleration Response | 18% faster |

| Fuel Filter Clogging | 62% reduction |

| Idle Stability | 31% smoother operation |

Data from fleet trials correlates additive use with 15% lower maintenance costs related to combustion issues.

Trend: Growing Adoption of Performance-Enhancing Fuel Additives in Commercial Transportation

Over 78% of North American freight carriers now mandate fuel additives in their maintenance programs, driven by EPA emission compliance and measurable ROI from fuel savings. This shift reflects industry-wide recognition of additives as essential for reliable, cost-effective operations.

Extended Engine Life via Wear and Corrosion Protection

Lubricity enhancement reduces wear in high-pressure diesel fuel systems

Quality additives form protective boundary layers on metal surfaces, reducing friction by up to 34% in fuel pumps and injectors. Research published in Tribology International (2023) shows these additives create microfilms capable of withstanding pressures exceeding 30,000 PSI in common-rail systems, helping maintain factory-specified clearances over time.

Corrosion and rust inhibition protect fuel system components over time

Advanced additive packages combine oxygen scavengers and metal deactivators to combat electrochemical degradation. They neutralize acidic compounds and form protective barriers on steel and aluminum surfaces. Independent testing reveals treated systems experience 78% less pitting corrosion after 5,000 operating hours compared to untreated ones.

Water separation prevents microbial growth and corrosion in storage and lines

Demulsifier additives accelerate water separation by 40%, concentrating moisture for easier filtration. This prevents microbial contamination in storage tanks and ice crystal formation in cold weather. Field data show a 90% reduction in filter-clogging biomass accumulation with regular additive use.

Balancing benefits: Assessing over-lubrication risks versus proven longevity gains

While excessive lubricity could theoretically impact emissions systems, third-party fleet studies confirm optimized dosing extends engine life by 18–22% without compromising aftertreatment efficiency. Following manufacturer-recommended dosage guidelines and conducting periodic used oil analysis ensures ideal wear protection.

Improved Fuel Efficiency and Operational Cost Savings

Fuel economy gains from optimized combustion and deposit removal

Additives improve diesel efficiency by enabling complete combustion and removing harmful deposits. Cleaner fuel systems minimize energy waste through optimized fuel atomization, recovering 2–4% of fuel economy lost to injector fouling. This improvement is supported by industry research on combustion optimization.

Detergents maintain clean fuel injectors and consistent fuel flow

Advanced detergent formulations prevent deposit buildup across critical components. Clean injectors ensure accurate spray patterns and flow rates, while clean combustion chambers avoid hot spots that degrade efficiency. Engines with over 100,000 miles of untreated operation often suffer 8–12% fuel waste—largely preventable with consistent additive use.

Data insight: 3–5% fuel savings observed in fleet trials with quality fuel additives

Controlled studies with long-haul fleets reveal consistent efficiency improvements:

| Fleet Size | Avg. MPG Improvement | Annual Fuel Savings |

|---|---|---|

| 50 trucks | 3.1% | $18,400 |

| 200 trucks | 4.7% | $127,000 |

These gains result from reduced engine friction, improved combustion timing, and lower parasitic losses from fuel pumps operating under strain.

Reliable Cold Weather Operation with Anti-Gel Additives

Cold Flow Improvement Ensures Diesel Performance in Sub-Zero Temperatures

Quality additives modify diesel's chemistry to resist paraffin wax solidification, maintaining fluidity down to -40°F. By depressing the cloud point—the temperature at which wax crystals form—they ensure uninterrupted fuel flow through filters and injectors, preventing power loss and engine strain in extreme cold.

Anti-Gel Additives Prevent Wax Crystallization and Fuel Filter Clogging

Anti-gel treatments disrupt wax crystal formation, avoiding the gel-like blockages that impair fuel delivery. Independent tests show treated diesel retains flow capacity three times longer than untreated fuel in freezing conditions. This protection also extends to storage tanks, minimizing microbial growth linked to water accumulation in cold environments.

Case Study: Arctic-Region Fleet Operations Dependent on Winterized Fuel Additives

A 12-month evaluation of Arctic logistics fleets found vehicles using anti-gel additives experienced 89% fewer cold-weather disruptions. According to industry research on winter fleet preparedness, additives enabled reliable fuel delivery across 2,000+ miles of sub-zero routes, with filter replacement intervals extending by 400% despite harsh conditions.

Reduced Emissions and Compliance with Environmental Standards

Cleaner Combustion Lowers Particulate Matter and Harmful Emissions

Adding certain chemicals to fuel helps engines burn better, cutting down on those pesky hydrocarbons that don't get fully burned in diesel motors. Tests show this can cut them by around 18 percent. When fuel burns completely, it means less stuff like PM2.5 particles and NOx gases coming out of exhaust pipes these tiny particles are really bad for city air quality. A recent paper published in Scientific Reports back in 2025 looked at this stuff and discovered something interesting fleets using these additives saw their carbon emissions drop by about 12% each year without losing any power from their engines. That's pretty impressive when we think about all the trucks and buses running around cities every day.

Fuel Stabilization Reduces Oxidation and Soot Formation

Stabilizers in advanced additives inhibit fuel degradation during storage, preventing resin and varnish formation that increases soot. This is especially important for biodiesel blends, which degrade faster than conventional diesel. Testing shows stabilized fuel maintains 97% combustion efficiency after six months of storage, compared to 82% in untreated samples.

Regulatory Alignment: How Fuel Additives Help Fleets Meet EPA and Euro Emissions Standards

Additives that have been certified actually work wonders when it comes to meeting those tough EPA Tier 4 and Euro VI standards. They cut down on all sorts of bad stuff in the air we breathe, slashing sulfur oxides (SOx) levels by around 23 percent and bringing hydrocarbon emissions down by about 30%. The folks at the Environmental Protection Agency definitely see value in these approved additives for their emissions control efforts. Trucking companies that stick with regular additive programs tell us they face roughly 40% fewer problems staying compliant. This means less money spent fixing old equipment and better preparedness when new regulations come along next year or so. Some fleet managers even mention how this approach saves them headaches during inspections.

FAQ

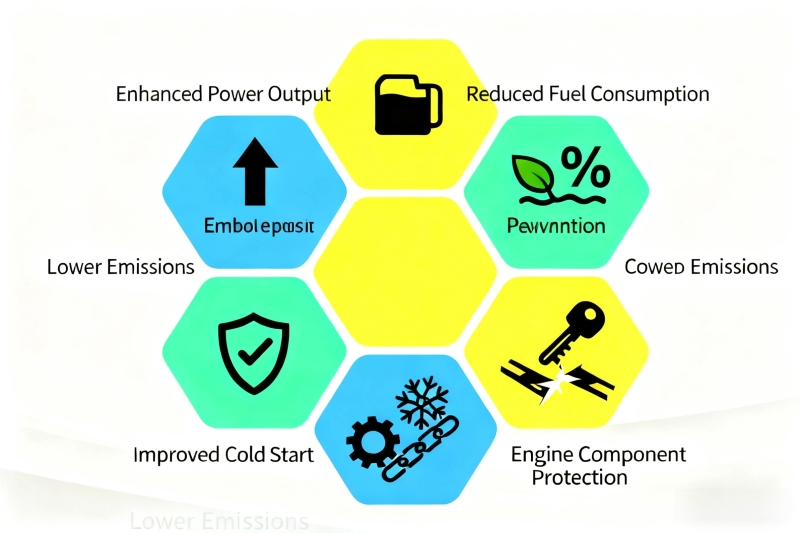

What are the primary benefits of fuel additives?

Fuel additives primarily enhance combustion efficiency, reduce power loss, improve cold startability, prevent deposit buildup, and extend engine life. They also help in lowering emissions and achieving fuel savings.

How do additives improve engine life?

Additives enhance lubricity, reduce wear, protect against corrosion, and improve fuel stability, thereby prolonging the life of engine components.

Can fuel additives help in cold weather conditions?

Yes, anti-gel additives modify fuel chemistry to prevent wax crystallization and ensure reliable flow in sub-zero temperatures, thereby preventing cold-weather disruptions.

Are fuel additives beneficial for emissions standards compliance?

Certified fuel additives help fleets comply with EPA and Euro emissions standards by reducing harmful emissions and improving combustion quality.

Table of Contents

-

Enhanced Engine Performance Through Cleaner Combustion

- How Fuel Additives Improve Engine Performance Through Optimized Combustion

- Deposit Control in Diesel Fuel Systems Prevents Power Loss and Maintains Efficiency

- Cetane Number Improvement Enhances Ignition Quality and Cold Startability

- Case Study: Improved Engine Responsiveness in Long-Haul Truck Fleets Using Performance Additives

- Trend: Growing Adoption of Performance-Enhancing Fuel Additives in Commercial Transportation

-

Extended Engine Life via Wear and Corrosion Protection

- Lubricity enhancement reduces wear in high-pressure diesel fuel systems

- Corrosion and rust inhibition protect fuel system components over time

- Water separation prevents microbial growth and corrosion in storage and lines

- Balancing benefits: Assessing over-lubrication risks versus proven longevity gains

- Improved Fuel Efficiency and Operational Cost Savings

- Reliable Cold Weather Operation with Anti-Gel Additives

- Reduced Emissions and Compliance with Environmental Standards

- FAQ