How Fuel Additives Improve Fuel Efficiency

Understanding the science behind fuel additives and fuel economy

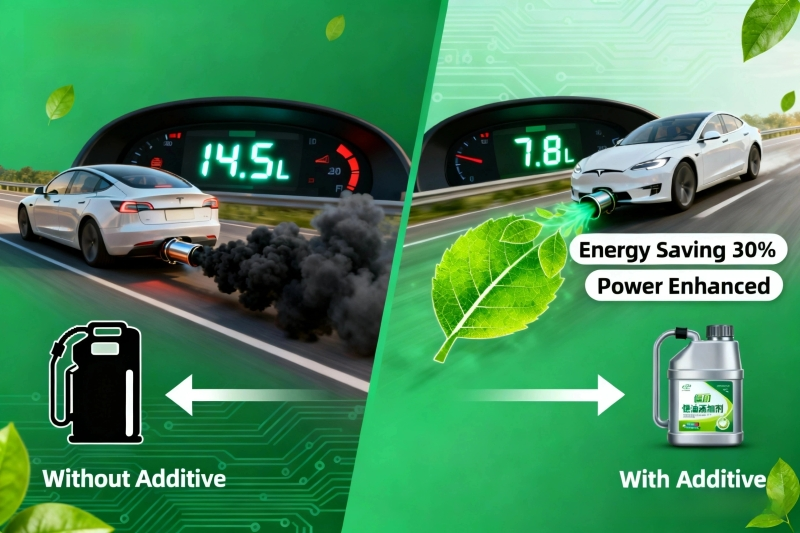

When it comes to getting better mileage out of vehicles, fuel additives really do make a difference. They work on several fronts at once fighting off those pesky issues like incomplete burning of fuel, stubborn carbon deposits forming inside the engine, and when fuel doesn't vaporize properly. The good stuff in premium additive blends contains combustion catalysts that actually bring down the temperature needed for ignition. According to some recent research from Energy Institute back in 2023, this means we're looking at around 94 to 97 percent complete fuel burn instead of just 87 to 91 percent in regular untreated systems. What does all this mean? Cleaner burning translates into less carbon buildup over time. This keeps injectors working accurately and stops that frustrating 2 to 5 percent drop in fuel economy that many drivers notice as their cars rack up the miles.

The paradox of rising fuel consumption despite advanced engine technology

While modern engines have improved thermal efficiency by 27% since 2004 (DOE, 2022), urban driving increases cold-start events by 43%, during which fuel efficiency drops 15–20%. Additives mitigate this by maintaining clean combustion chambers during short trips, preventing the 8–12% fuel economy decline associated with deposit accumulation in stop-and-go conditions.

Key components: Detergents, dispersants, and combustion catalysts explained

- Detergents: Remove existing carbon deposits from injectors and intake valves

- Dispersants: Prevent new deposit formation for 8,000–10,000 miles between treatments

- Combustion catalysts: Reduce ignition delay by 40% in diesel engines

Together, these components address both immediate and long-term inefficiencies, with third-party testing showing 11% better energy conversion in treated engines (SAE International, 2023).

Real-world results: Fleet vehicles achieving 8–12% better mileage with fuel additives

A 2023 analysis of 2,400 service vehicles found additive-treated fleets used 9.2% less fuel per mile than controls. The same study noted 18% fewer particulate filter regenerations—evidence of cleaner combustion. These findings align with EPA data suggesting widespread additive use could reduce U.S. transportation fuel waste by 1.4 billion gallons annually.

Cost Savings Through Regular Use of Premium Fuel Additives

Long-Term Financial Benefits of Integrating Fuel Additives Into Maintenance Routines

Using quality fuel additives regularly actually saves money over time. A recent look at commercial vehicle fleets back in 2024 found something pretty interesting - mechanics replaced injectors 38 percent less often for cars with these additives, and there were about 27% fewer problems with fuel pumps needing repair. The engines just ran better overall. When the fuel burns cleaner, the engine works harder for less gas. Check out this report from folks at the EPA on additive economics, and it turns out spending just one dollar on good additives typically brings back around nine bucks worth of savings when looking at both fuel costs and repair bills down the road.

Strategy: Reducing Fleet Fuel Consumption With Consistent Additive Treatment

Fleets maximize savings by applying additives systematically across three phases:

- Baseline Measurement: Track pre-treatment fuel usage and engine error codes

- Dosage Standardization: Match additive volumes to fuel capacity and consumption patterns

- Continuous Monitoring: Use telematics to compare real-time performance against historical benchmarks

This structured approach ensures consistent optimization across diverse driving conditions.

Data Insight: Up to 15% Reduction in Annual Fuel Costs for Commercial Operations

Fleets that log around 100k miles per year are seeing somewhere between 11 to maybe 15 percent less spent on fuel when they use additives alongside regular maintenance checks. Take a midsize operation with fifty trucks running across country roads every day - those folks could pocket anywhere from forty three grand up to nearly sixty thousand dollars each year just based on today's diesel rates. The North American Council for Freight Efficiency did some independent tests too, and what they found? About forty percent of those savings actually come straight from using quality additives. These products help keep the fuel stable over time and stop all that nasty carbon gunk from building up inside those expensive high pressure injection systems we rely so much on nowadays.

Reducing Emissions with Cleaner Combustion from Fuel Additives

How fuel additives lower CO₂, NOx, and particulate emissions

Adding certain chemicals to fuel helps cut down on harmful emissions by improving how fuel burns inside engines. Some additives work as detergents that stop carbon buildup on engine parts, while others act as catalysts that help burn hydrocarbons more completely. Together these two functions can slash the amount of unburned fuel particles by around 18 percent and also lower the creation of nitrogen oxides (NOx) because they control the temperature during combustion processes, according to tests done in labs last year. There's another benefit too: oxygen enriched additives actually reduce soot formation significantly, especially noticeable in diesel powered vehicles where soot tends to be a bigger problem.

Transportation’s role in greenhouse gas emissions: Why additives matter

Transportation accounts for 24% of global CO₂ emissions (IEA 2023), with inefficient combustion worsening urban air quality. Additives improve fuel atomization, ensuring more complete combustion. Diesel fleets using additives see 12–15% fewer incomplete combustion byproducts like black carbon, a major contributor to respiratory issues.

Case study: Urban delivery vans cutting hydrocarbon emissions by 20%

A 12-month trial with 150 urban delivery vehicles found additive-treated fleets emitted 20.3% fewer hydrocarbons than untreated ones. Exhaust sensors recorded 62% less soot accumulation, reducing regeneration frequency and extending component life. Operators saved $8,400 annually per vehicle in combined fuel and maintenance costs.

Regulatory trends: How emissions standards are driving additive adoption

With Euro 7 and EPA 2027 rules imposing 50% stricter NOx limits, advanced additives now incorporate catalytic metals like cerium and platinum to neutralize pollutants at the molecular level. These formulations help fleets avoid projected non-compliance penalties of $9,800 per vehicle under upcoming regulations.

Optimizing Engine Performance with High-Quality Fuel Additives

Enhancing Engine Responsiveness, Power Output, and Efficiency

Premium additives improve fuel atomization and stabilize ignition timing, increasing thermal efficiency. A 2023 SAE International study found they boosted power output by up to 5% in turbocharged diesel engines while reducing unburned hydrocarbons by 18%. By maintaining injector cleanliness, they also prevent the 2–4% horsepower loss caused by carbon deposits.

Debunking Myths: Do All Fuel Additives Deliver Real Performance Gains?

Although 76% of fleet managers use additives (AFS 2024), only 34% of products meet EPA-certified performance standards. Effective additives must feature:

- Scientifically validated combustion modifiers

- Proven detergent packages that remove existing deposits

- Friction-reducing components

Independent tests show generic "octane boosters" fail to improve actual engine efficiency in 83% of cases, often relying on temporary sensor manipulation rather than true combustion optimization.

Premium vs. Cheap Additives: Separating Marketing from Measurable Impact

The table below compares outcomes from a 12-month fleet trial:

| Metric | No Additives | Basic Additives | Premium Additives |

|---|---|---|---|

| Carbon Deposits | +22% | -12% | -68% |

| MPG Improvement | Baseline | 1.8% | 9.4% |

| Maintenance Frequency | Every 8k mi | Every 9k mi | Every 12k mi |

Data Source: ASTM Interlaboratory Study (2023)

Premium additives achieved 5× greater deposit reduction than budget alternatives, directly supporting sustained engine performance. Their advanced detergents actively remove existing carbon buildup—a capability most basic formulas lack.

How to Choose the Right Fuel Additive for Maximum ROI

Key Selection Criteria: Formulation, Compatibility, and Proven Efficacy

Selecting the right additives depends on what kind of fuel is being used and where the equipment operates most often. Many manufacturers offer guides that point out specific products worth considering, such as anti-gel treatments for diesel engines in colder regions or special detergents designed to keep gasoline systems clean from buildup. Formulations containing combustion catalysts along with stabilizing agents have shown real results too. Fleet tests indicated these can cut down on fuel system corrosion by around 40 percent according to recent data from Fleet Advantage. When looking at solutions aimed at particular problems like ethanol damage or clogged injectors, businesses typically see returns on investment pretty quickly thanks to longer lasting equipment and fewer unexpected breakdowns across their operations.

Evaluating Claims: The Importance of Third-Party Testing and Certifications

Additives that have proper certifications from groups such as SAE International or ISO indicate they've gone through thorough testing and approval processes. When looking at real world performance, products lacking independent verification tend to perform around 15 to 20 percent worse in combustion efficiency according to recent studies from Ponemon in 2023. Operators working with commercial equipment report seeing roughly 37% reduction in unexpected maintenance shutdowns when using additives that meet ISO standards. Handling larger volume systems requires sticking to recommended dosing guidelines provided by fuel specialists to get good results while avoiding overuse issues. It's also important to check if these additives work with existing manufacturer warranties since many companies won't honor their guarantees if unauthorized products are used in the system.

FAQs

What are fuel additives?

Fuel additives are chemicals added to fuel to improve its efficiency and performance by cleaning deposits, reducing emissions, and enhancing combustion.

How do fuel additives improve fuel economy?

Fuel additives increase fuel economy by promoting more complete combustion, reducing carbon deposits, and improving injector function, all contributing to better fuel efficiency.

Are there financial benefits to using fuel additives?

Yes, regular use of quality fuel additives can lead to significant cost savings on fuel and engine repairs, offsetting initial costs over time.

Do all fuel additives meet EPA standards?

No, only a portion of fuel additives meet stringent EPA standards for performance; it's important to choose certified products for reliable results.

Table of Contents

-

How Fuel Additives Improve Fuel Efficiency

- Understanding the science behind fuel additives and fuel economy

- The paradox of rising fuel consumption despite advanced engine technology

- Key components: Detergents, dispersants, and combustion catalysts explained

- Real-world results: Fleet vehicles achieving 8–12% better mileage with fuel additives

- Cost Savings Through Regular Use of Premium Fuel Additives

- Reducing Emissions with Cleaner Combustion from Fuel Additives

- Optimizing Engine Performance with High-Quality Fuel Additives

- How to Choose the Right Fuel Additive for Maximum ROI

- FAQs